Double Suction Split Case Pump Cos125

Basic Info.

| Model NO. | COS125-290 (1450rpm) |

| Position of Pump Shaft | Horizontal Pump |

| Pump Casing Combined | Horizontal Split Pumps |

| Mounting Height | Suction Centrifugal |

| Impeller | Closed |

| Usage | Pump, Pumps, Circulating Pump, Irrigation Pumps |

| Voltage | 220V/380V/400V/415V/440V/460V |

| Material | Cast Iron, Cast Steel, S.S304, S.S316 |

| Transport Package | Standard Export Wooden Packing |

| Specification | DN200/DN125mm |

| Trademark | SanChang |

| Origin | Changsha, Hunan, China |

| HS Code | 8413709990 |

| Production Capacity | 200 Sets/Month |

Product Description

Description

COS series split case pump/split casing pump/double suction centrifugal pump is a new generation of single stage double suction centrifugal split case pump with high performance and reliability, it is mainly applied to liquid transferring occasions like water works, air conditioner circulation water, heat supply pipe network system, building water supply, irrigation, drainage pump station, power station, industrial water supply system, fire fighting system, ship industry, water supply and drainage for mines, etc.

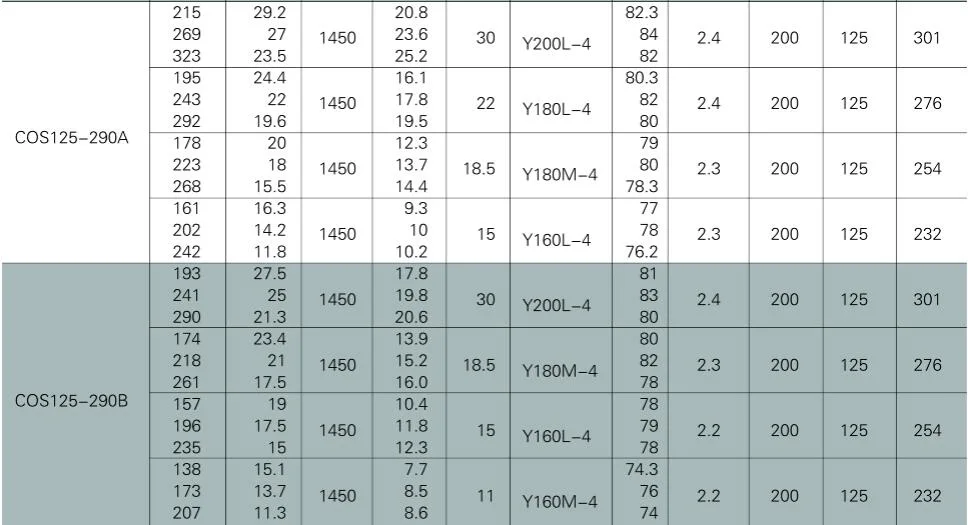

Performance &Specifications

Material of flow passage components:

The COS series Split case pump/Split casing pump/Double suction centrifugal pump could be customized withdifferent material, main material configuration followed :

| Recommended Material Configuration (For reference only) | |||||

| Item | Clean water | Drink water | Sewage water | Hot water | Sea water |

| Case & Cover | Gray iron (HT250) | S.S304 | Ductile iron (QT500) | Cast Steel | Duplex S.S 2205 |

| Impeller | Gray iron (HT250) | S.S304 | Ductile iron (QT500) | 2Cr13 | Duplex S.S 2205 |

| Wearing ring | Gray iron (HT250) | S.S304 | Ductile iron (QT500) | 2Cr13 | Duplex S.S 2205 |

| Shaft | C.S 45 | S.S420 | 40Cr | 40Cr | Duplex S.S 2205 |

| Shaft sleeve | C.S 45 | S.S304 | S.S304 | S.S304 | Duplex S.S 2205 |

| Remarks: detailed material list will according to liquid and site conditions | |||||

1) Features:

a) Compact structure

b) Attractive design

c) High efficiency, steady performance

d) High flow, medium pressure

e) High concentricity of components

2) Applications:

a) Waterworks

b) Circulation water for air-condition

c) Water supply for industry and building

d) Irrigation and drainage pumping station

e) Power stationf) Fire fighting